Quality Inspections

JFE Technos conducts equipment investigation/diagnosis through nondestructive inspection and mechanical testing and keeps equipment in a safe condition utilizing our outstanding technologies and know-how.

We also perform diagnoses of corrosion, fatigue and deterioration and propose the optimum repair/reinforcement method for each condition.

Quality Inspections

Radiographic Testing: RT

As in medical X-ray examinations, internal defects can be detected by applying radiation to the inspection target.

Applications

Welds of structures (ships, cranes, bridges, etc.), internal defects in materials, piping welds, etc.

Ultrasonic Testing: UT

Internal defects are detected from the reflected ultrasonic wave when ultrasonic vibration is applied to the inspection target. It is possible to measure the depth and position of defects, the length of bolts, etc.

Applications

Welds of structures, materials, measurement of plate thickness and bolt length, etc.

Magnetic Particle Testing: MT

Surface defects are detected by applying a magnetic flux to the specimen surface.

Applications

Welds, materials, machined parts, etc.

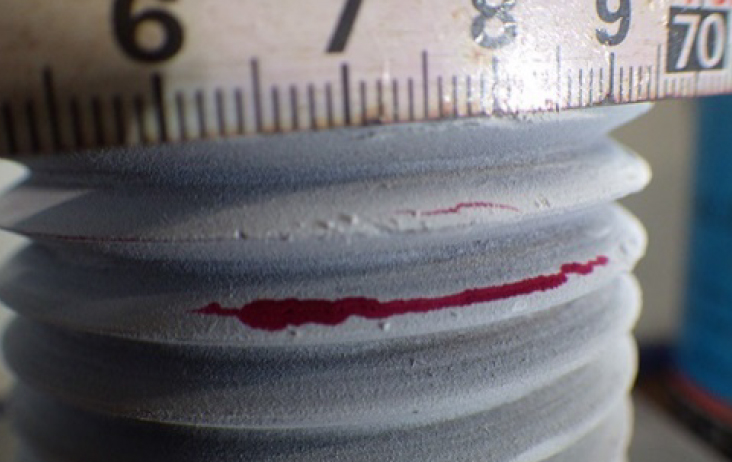

Penetrant Testing: PT

Also called dye penetrant testing or liquid penetrant testing. Surface defects are detected by seepage of a penetrating liquid which is coated on the specimen surface.

Applications

Welds of structures, materials, nonferrous materials, etc.

Eddy Current Testing: ET

Surface defects are detected from changes in the current when an eddy current is generated on the surface.

Applications

Inspection of heat exchanger tubes, welds in cranes (from above the paint film)

Strain Gauge Testing: ST

Measurement of stress by attaching a strain gauge to the test specimen.

Applications

Remaining life diagnosis of cranes, etc., stress measurement during welding, load measurement, tension measurement

Positive Material Identification: PMI

Identification of alloy elements from the wavelength of light when sparks are generated on a test specimen.

Applications

Confirmation that the material of imported products and materials is the same as indicated in the mill sheet, mechanical testing.

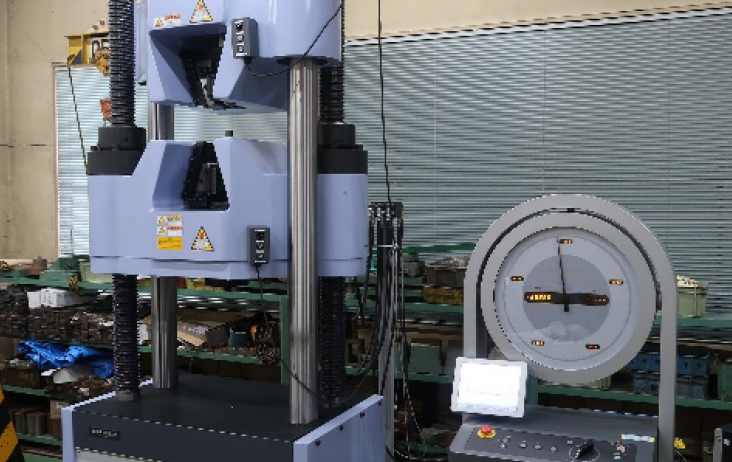

Mechanical Testing

Testing to confirm the strength of welds and materials. Includes tensile tests, bending tests hardness tests, etc. We can also respond to requests for macro- and microscopic observation of the material microstructure and welds at high magnifications.

Failure Investigation

Observation of the fracture surface of members that fail during use, and investigation of damage information.

Applications

Failure investigation of rolling mill shafts, mounting bolts of cranes and other equipment, etc.

Careers

Careers