Hydroelectric Power Generation

Hydroelectric Power Generation is a method of generating electricity using water.

Hydroelectric Power Generation produces electricity by sending water from a higher location to a lower location where generator is installed. In Japan, where has rich water resources, Hydroelectric Power Generation has been very actively conducted since early times. Hydroelectric Power Generation used to operate only in large dams before, but industrial development has made it possible to generate electricity even with relatively small facilities that use river water, agricultural water, and water supply and sewage system. As a result, Hydroelectric Power is becoming more widely used.

JFE Technos’s Hydroelectric Power Generation

With the accumulated technologies of the JFE Engineering Group, we can meet various customer needs from planning, designing and construction of hydroelectric power plants to delivery and installation of water turbine generators. We work toward “local production and consumption” of electric power by supporting local farming, and contribute to “carbon-neutral” by reducing CO2 emissions to zero by 2050 and achivement of a sustainable society.

Project

Namie-machi, Futaba-gun, Fukushima “Oogaki Dam”

Overview

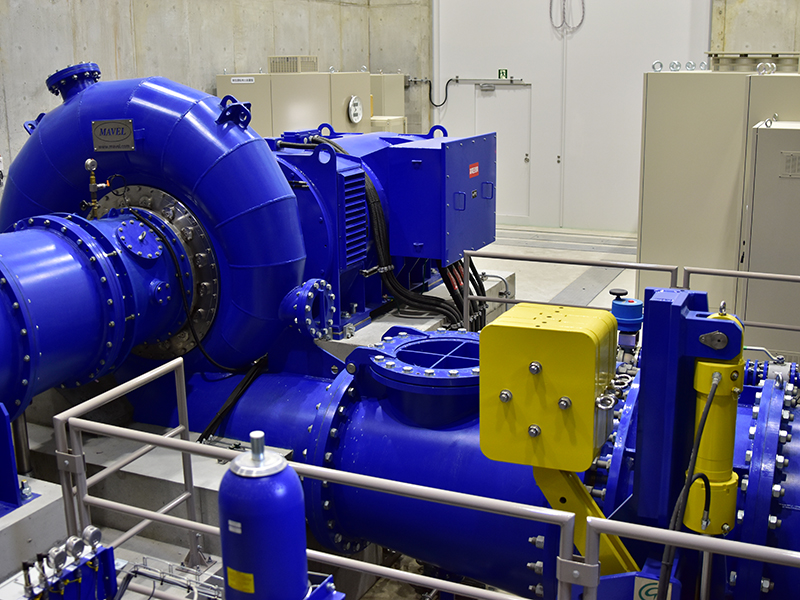

Construction of this hydroelectric power plant started in April 2023 as a hydroelectric power generation project utilizing agricultural water in Oogaki dam in Namie-machi, Futaba-gun, Fukushima prefecture, and a 1401kW water turbine and generator was installed at the Oogaki Dam to generate electricity using water pressure caused by the difference in water level at the dam. The generated power is sold entirely through “renewable energy feed-in Tariff” (FIT) system”.

The project supports the town’s firming industry and contributes to “carbon neutral” achieving virtually zero CO2 emissions by 2050.

Challenges

This is the first challenge in the Soso area that hydroelectric power generation is constructed inside a facility of an agricultural dam. The construction schedule must be adjusted so that it does not disturb the operation of the dam for irrigation.

Contents of proposal

- ①Branch pipe connection from existing hydraulic iron pipe to water turbine.

As the existing hydraulic iron pipe is used for irrigation and keeping the usual river water flow, for the construction of a branch pipe connecting to the said pipe, the water flow to the pipe must be stopped. Therefore, before construction, we propose that the water is stored to the maximum storage capacity in off season for irrigation, so that the water is released from the flood discharge gate at the top of the dam to keep the usual river water flow. - ②Water turbine Trial operation in parallel with irrigation season operation

When conducting various trial operations with the water turbine, the adjustments of flow rate and timing for discharge shutdown at the dam side were controlled and conducted in parallel with irrigation operations.

Outline of delivered system

- 1Equipment manufacturing

Francis turbine (recoil turbine), Generator (3-phase synchronous generator),

Generator control panel, In-plant panel, Generator panel, Interconnection panel, DC power supply equipment - 2Installation/trial operation (Water turbine trial operation in parallel with irrigation season operation.)

- 3Electrical equipment installation

- 4Civil engineering works

Careers

Careers