Bridge Maintenance

There are about 700,000 bridges in Japan. Many were built during Japan’s era of high economic growth from the mid-1950s to the early 1970s, and the bridge piers now need repair, reinforcement and maintenance.

In order to keep bridge infrastructure in good condition, JFE Technos responds to requests with the combined technologies and know-how of the JFE Group.

Examples of Bridge Maintenance Work

Seismic reinforcement work

Life extension work

Inspection, investigation, examination and diagnosis

Example of Quality Inspection

Equipment investigation and diagnosis are carried out through nondestructive inspection and mechanical testing, and equipment is maintained in a safe condition with outstanding technologies and know-how. We can diagnose corrosion, fatigue and deterioration and propose appropriate repairs and reinforcement for each condition. We also perform diagnoses of large-scale cranes, motors and other equipment and can propose remaining life diagnosis.

Delivery Record

Bridge pier reinforcement by reinforced concrete jacketing

Bridge pier reinforcement by reinforced concrete jacketing ridge fall prevention device (buffer chain type)

ridge fall prevention device (buffer chain type) Buffer pin type horizontal force dispersing structure

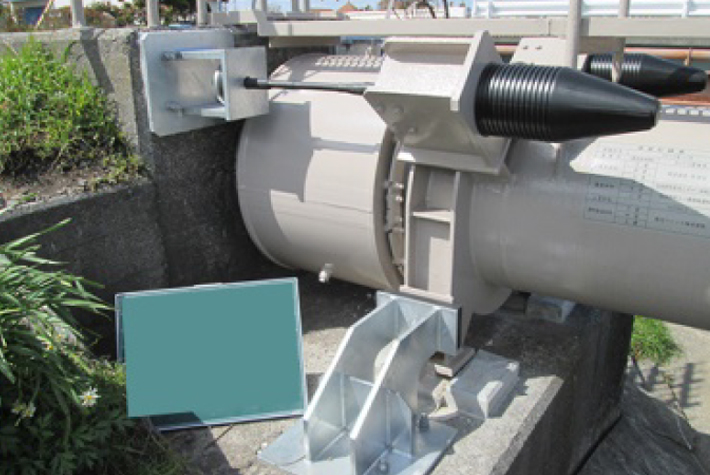

Buffer pin type horizontal force dispersing structure Bridge fall prevention device of water pipe bridge

Bridge fall prevention device of water pipe bridge Replacement of storm cables and stays of suspension bridge, repair of cross-section of floor slab, replacement of extension device, etc.

Replacement of storm cables and stays of suspension bridge, repair of cross-section of floor slab, replacement of extension device, etc. Replacement of metal fittings (turnbuckles) of main cable anchor mounting part

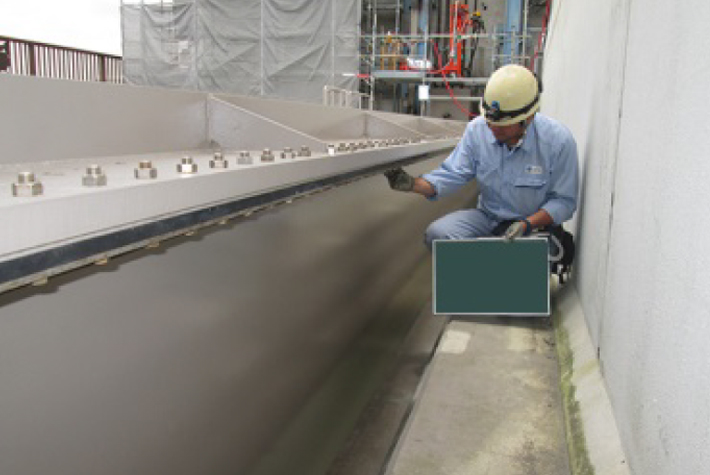

Replacement of metal fittings (turnbuckles) of main cable anchor mounting part Partial replacement for chipped cross-section due to corrosion of water pipe (executed when installing a bridge fall prevention device of water pipe bridge)

Partial replacement for chipped cross-section due to corrosion of water pipe (executed when installing a bridge fall prevention device of water pipe bridge) Removal and installation of main roller of sluice

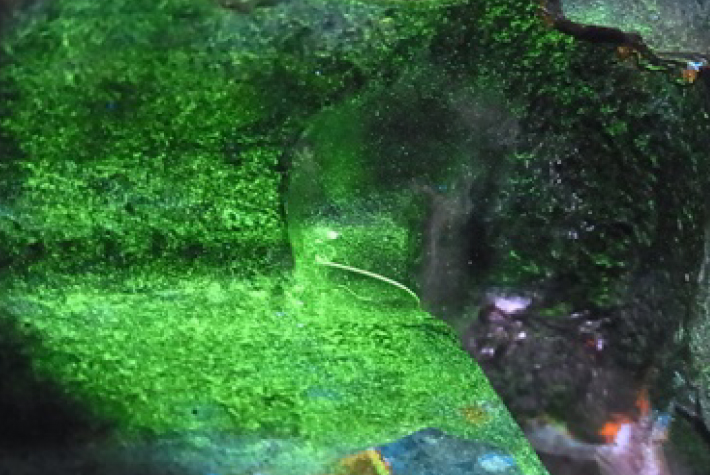

Removal and installation of main roller of sluice Inspection of sluice (watertight rubber part)

Inspection of sluice (watertight rubber part) Magnetic particle test for welded part on site

Magnetic particle test for welded part on site Radiographic test for welded part on site

Radiographic test for welded part on site Magnetic particle testing for fatigue crack

Magnetic particle testing for fatigue crack Non-destructive test by X-ray vehicle

Non-destructive test by X-ray vehicle Careers

Careers